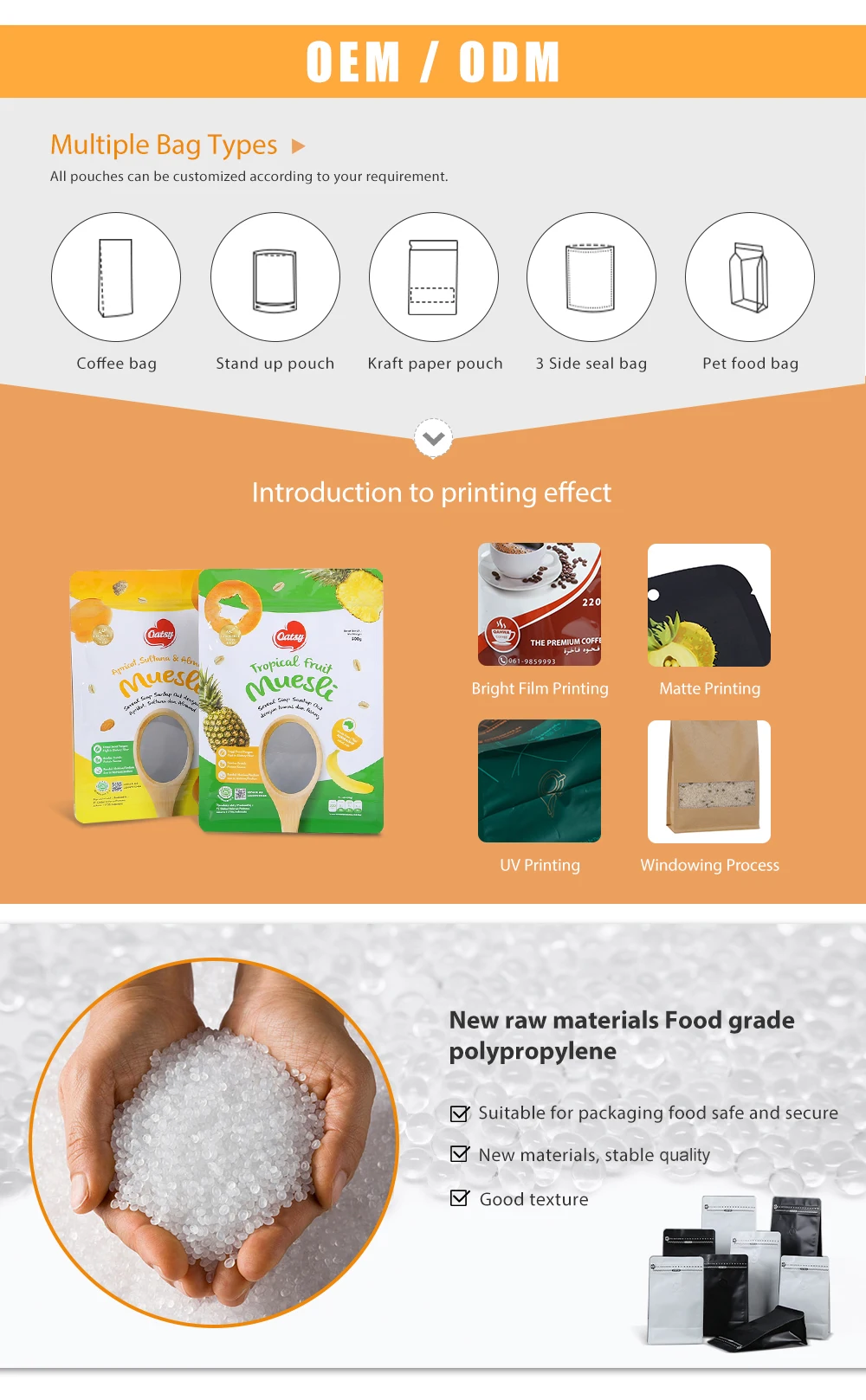

Custom Printed Square PE Plastic Ziplock Bags with Valve Zipper Flat Bottom Side Gusset Coffee Beans Packaging represents an innovative solution for businesses seeking premium flexible packaging that combines functionality with visual appeal. These specialized containers feature a unique square design that maximizes shelf presentation while providing optimal storage efficiency for coffee products and other premium consumables. The polyethylene construction ensures exceptional barrier protection against moisture, oxygen, and external contaminants, making these bags ideal for maintaining the freshness and aromatic qualities of roasted coffee beans, ground coffee, tea leaves, nuts, dried fruits, and various specialty food products. The integrated valve zipper system allows for controlled degassing of freshly roasted coffee while maintaining an airtight seal, addressing the specific requirements of coffee packaging where carbon dioxide release is essential without compromising product integrity. The flat bottom construction provides excellent stability for retail display and storage applications, while the side gussets create expanded capacity and facilitate easy filling processes during production operations. Professional custom printing capabilities enable brand differentiation through high-resolution graphics, logos, and product information that maintain clarity and color vibrancy throughout the product lifecycle. The square configuration optimizes packaging efficiency compared to traditional round or oval formats, allowing for improved transportation logistics and reduced storage space requirements. These versatile containers serve multiple industries beyond coffee packaging, including pharmaceutical products, cosmetic items, electronic components, and industrial materials where moisture protection and tamper-evident sealing are critical requirements. The valve mechanism incorporates advanced engineering that permits one-way gas exchange, preventing bag expansion from internal pressure buildup while blocking external air infiltration that could compromise product quality. The bottom gusset design enhances structural integrity and provides a stable base that prevents tipping during handling and display, making these bags particularly suitable for retail environments and commercial distribution channels. Quality polyethylene materials ensure compatibility with various filling temperatures and maintain flexibility across different storage conditions, supporting diverse application scenarios from automated packaging lines to manual filling operations. The ziplock closure system features durable track construction that withstands repeated opening and closing cycles, providing consumers with reliable resealing capabilities that extend product shelf life after initial opening. Custom printing options accommodate complex design requirements including multi-color graphics, gradient effects, product windows, and regulatory labeling, enabling comprehensive brand communication strategies. The side gusset configuration expands packaging volume while maintaining a compact profile when empty, optimizing shipping costs and storage efficiency for manufacturers and distributors. These bags demonstrate exceptional puncture resistance and tear strength, ensuring product protection throughout supply chain handling from manufacturing facilities to end consumers. The valve technology prevents oxidation and flavor deterioration in sensitive products while allowing natural degassing processes that are essential for optimal coffee quality maintenance. Advanced printing techniques ensure excellent adhesion and durability of graphics under various environmental conditions, maintaining professional appearance throughout distribution and retail display periods. The square format facilitates automated packaging equipment integration, supporting high-speed production lines while maintaining consistent seal integrity and print registration. Flexible packaging solutions like these custom printed bags offer significant advantages over rigid containers including reduced material usage, lower transportation costs, and improved sustainability profiles through optimized resource consumption. The combination of valve technology and ziplock convenience creates user-friendly packaging that appeals to both commercial buyers and end consumers who value freshness preservation and ease of use. Manufacturing expertise in flexible packaging ensures consistent quality standards and reliable performance across large production volumes, supporting businesses that require dependable packaging solutions for their premium products. The polyethylene material selection provides excellent chemical resistance and maintains integrity when exposed to oils and aromatic compounds commonly found in coffee and specialty food applications. These innovative containers address evolving market demands for packaging that combines practical functionality with attractive presentation, enabling brands to differentiate their products in competitive retail environments while ensuring optimal product protection and consumer satisfaction.

Custom Printed Square PE Plastic Ziplock Bags with Valve Zipper Flat Bottom Side Gusset Coffee Beans Packaging

- Overview

- Recommended Products

Why Choose Us

Item |

Tea/Rice/Snack/Vacuum/Pet Food/Food Packaging Bag |

Material |

BOPP Metalized CPP,PET/VMPET/PE,or as your request |

Feature |

Strong sealing strength/good barrier/excellent printing surface |

Colors |

Up to 8 colors gravure printing |

Edge design |

Heat seal/easy tear notch |

Style |

Stand up pouch/heat seal bag/mid sealed flat bag/aluminum foil bag |

Special design |

Easy tear notch,ziplock(reclosable) if necessary |

Price |

Need to check as per your packaging specification and the quantity |

MOQ |

10000pcs |

Sample |

Free sample if have stock,sample charge are refundable after place an order |

Packing |

Inner poly bag,outer carton |

Payment term |

T/T |

1. What is your terms of payment?

50% deposit and 100% cylinder cost within 7 days after PO is confirmed, balance before shipment by TT.

2. What is the lead time?

It usually takes 15 to 21 days after sample confirmation and receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

3. What is your terms of delivery?

We accept EXW,FOB,CIF,etc. You can choose the one which is the most convenient or cost effective for you.

4. How to solve the quality problems after sales?

Take photos of the problems and send to us. We will make a satisfied solution for you within 24 hours after we confirm the problems.

5. Is it OK to print my logo on the product?

Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

6. You are manufacturer or trading company?

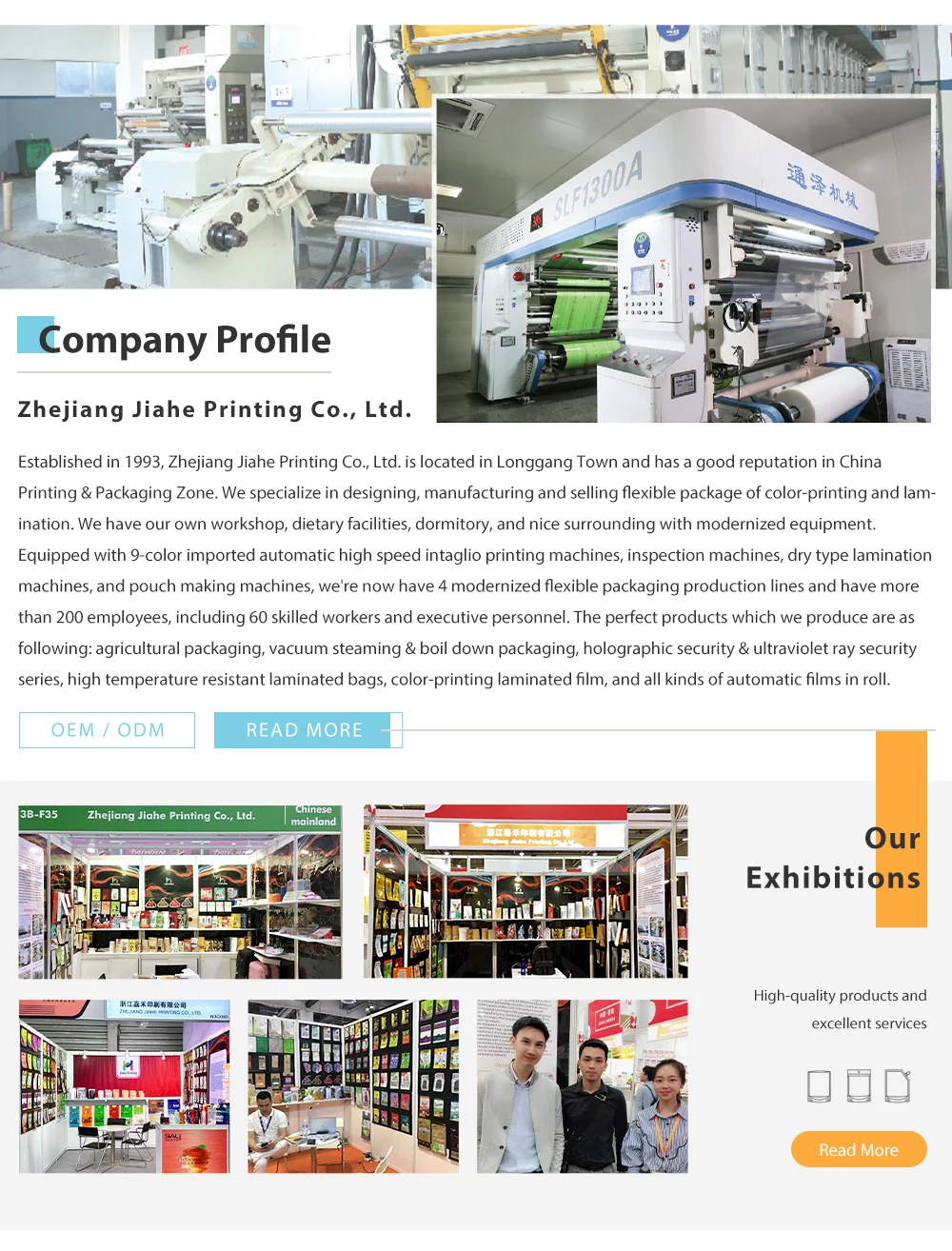

We are factory, we are a leading packaging manufacturer, welcome to visit our factory at anytime.

7. Why do I choose the package bags from Jiahe Printing?

A.With over 19 years’ experience, Jiahe Printing is always focusing on offering superior packaging products to its customers.

B. Eco friendly &recycled material with ECONOMICAL COST.

C. Understand the market, walk in front, offer a lot of special bags.

D. Quality Inspection

E. Jiahe’s business covers all over the world, such as USA, Australia, New Zealand, Europe, South Asia,etc.